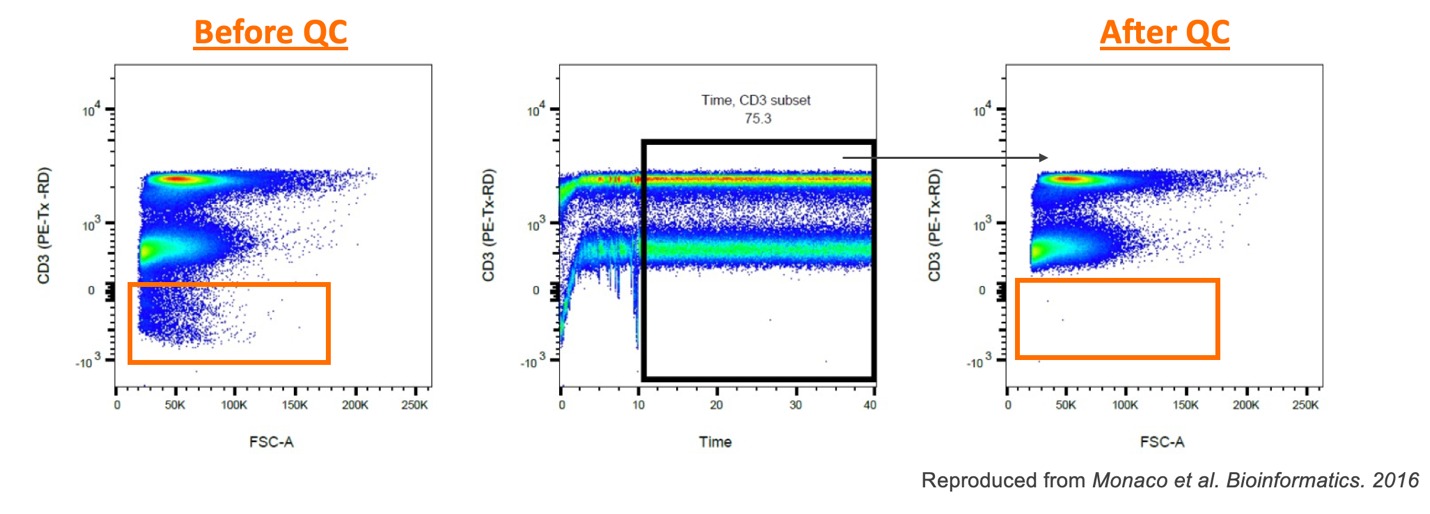

Sample QC is crucial in sample analysis.

Despite all care during samples preparation and instrument setup, issues can arise when running the acquisition on the instrument (i.e. most common ones are clogs and air bubbles). Those issues may result in the alteration of the measurement of the parameters which can lead to false discovery.

Figure 1. Why to run sample quality control (QC)

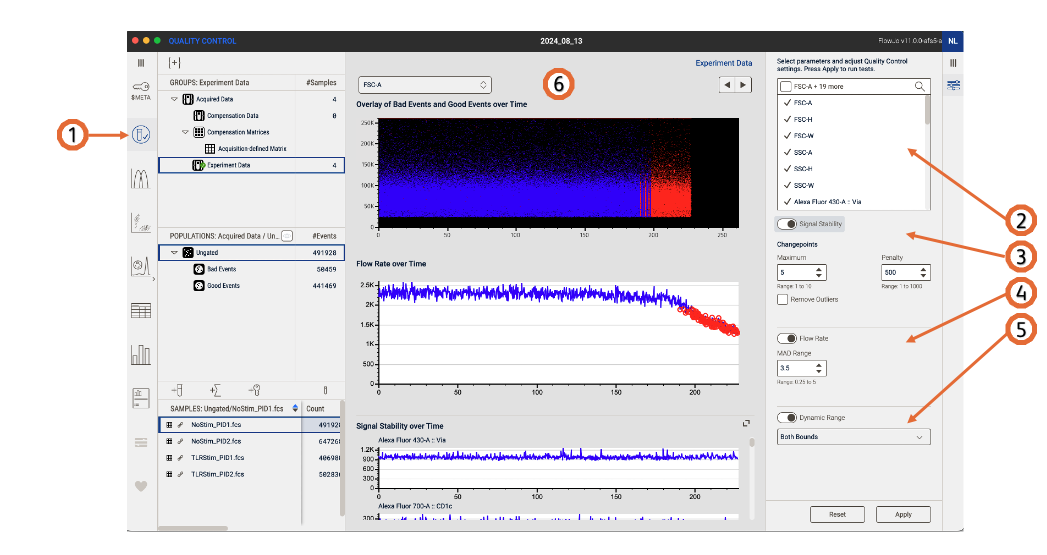

There many great R based algorithms available, but we came up with our own integrated QC tool. In the navigation bar, click on the “Quality control” icon. Select parameters and adjust quality control settings in the “Properties panel” (Figure 2)

Figure 2. Sample quality control (QC)

Signal stability

- Changepoints maximum: the maximum number of change points that can be detected for each channel

- Changepoints penalty: raise the penalty value to be less strict in the detection of anomalies

Flow rate

MAD range: shows deviations from peak range, lower the value to be more strict (Default 3.5 – Range 0.25 to 5)

Dynamic range

Select whether the dynamic range check should be performed on the upper limit, the lower limit, or both.

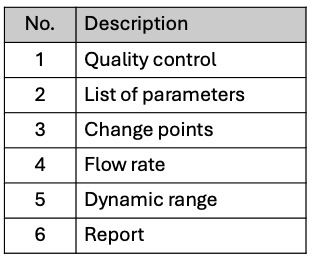

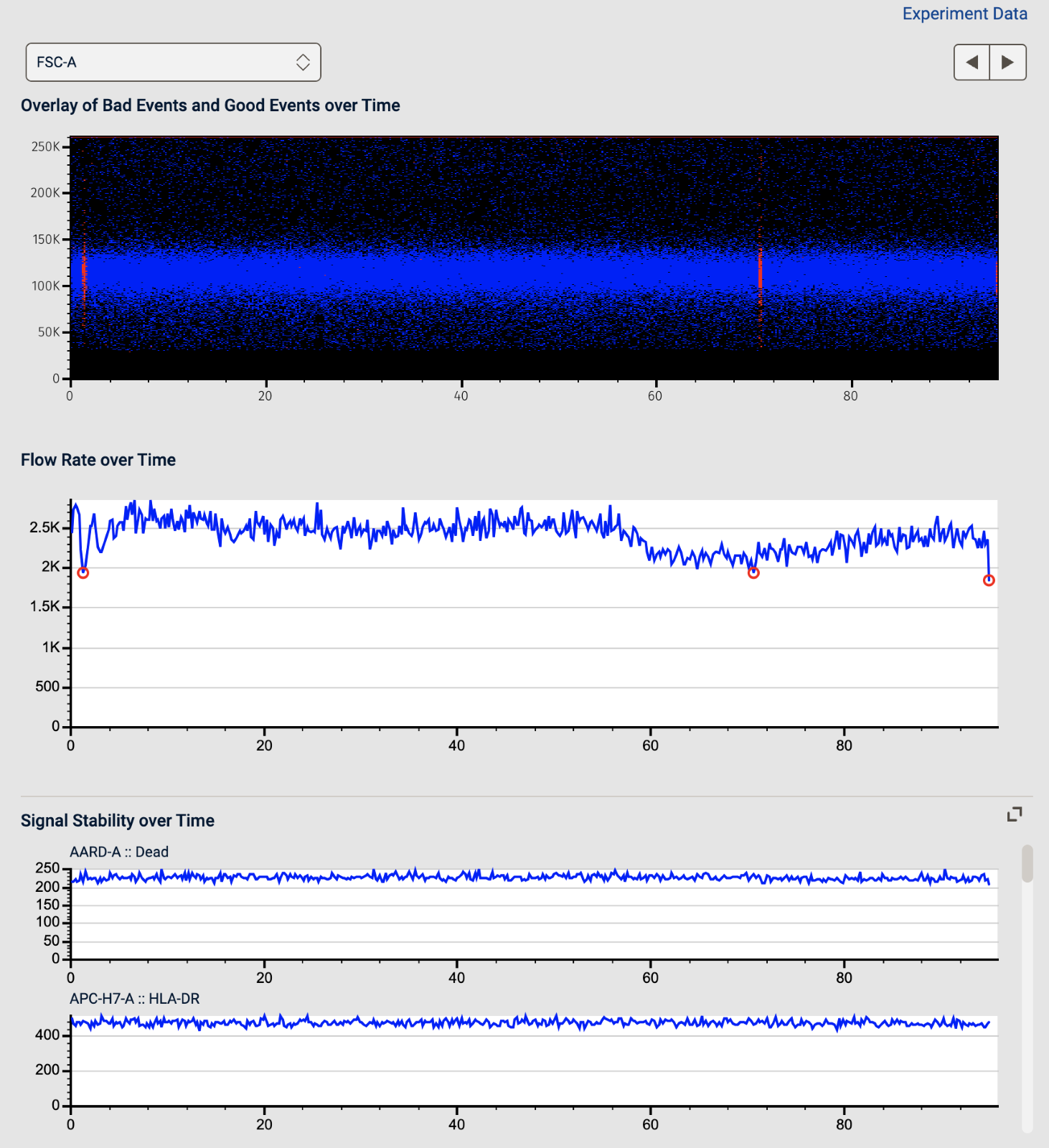

On completion

After running QC on your data, a green check mark will be on displayed on the group “Experiment Data”, a set of Good Events/Bad Events populations will be created (displayed in the Analysis tree: Populations panel) and the QC report will display on the Discovery panel. In the Overlay of Bad Events and Good events over Time plot, blue are the good events and red events are the events removed by QC. You can also select the Y axes with the parameter of your choice.

Figure 3. A report for one sample within the QC plotform